The History of Air Curtains for Energy-Efficient Refrigerated Transport: The Origin of BlueSeal

Introduction: Tracing the History of Air Curtains for Energy-Efficient Refrigerated Transport

In this blog, Brightec founder Hans Opdam discusses the research project that led to the development of commercial vehicle air curtains during his time at Econcern, a now-defunct company specialising in renewable energies. This work became the foundation for BlueSeal® air curtains-a breakthrough in the history of air curtains for energy-efficient refrigerated transport.

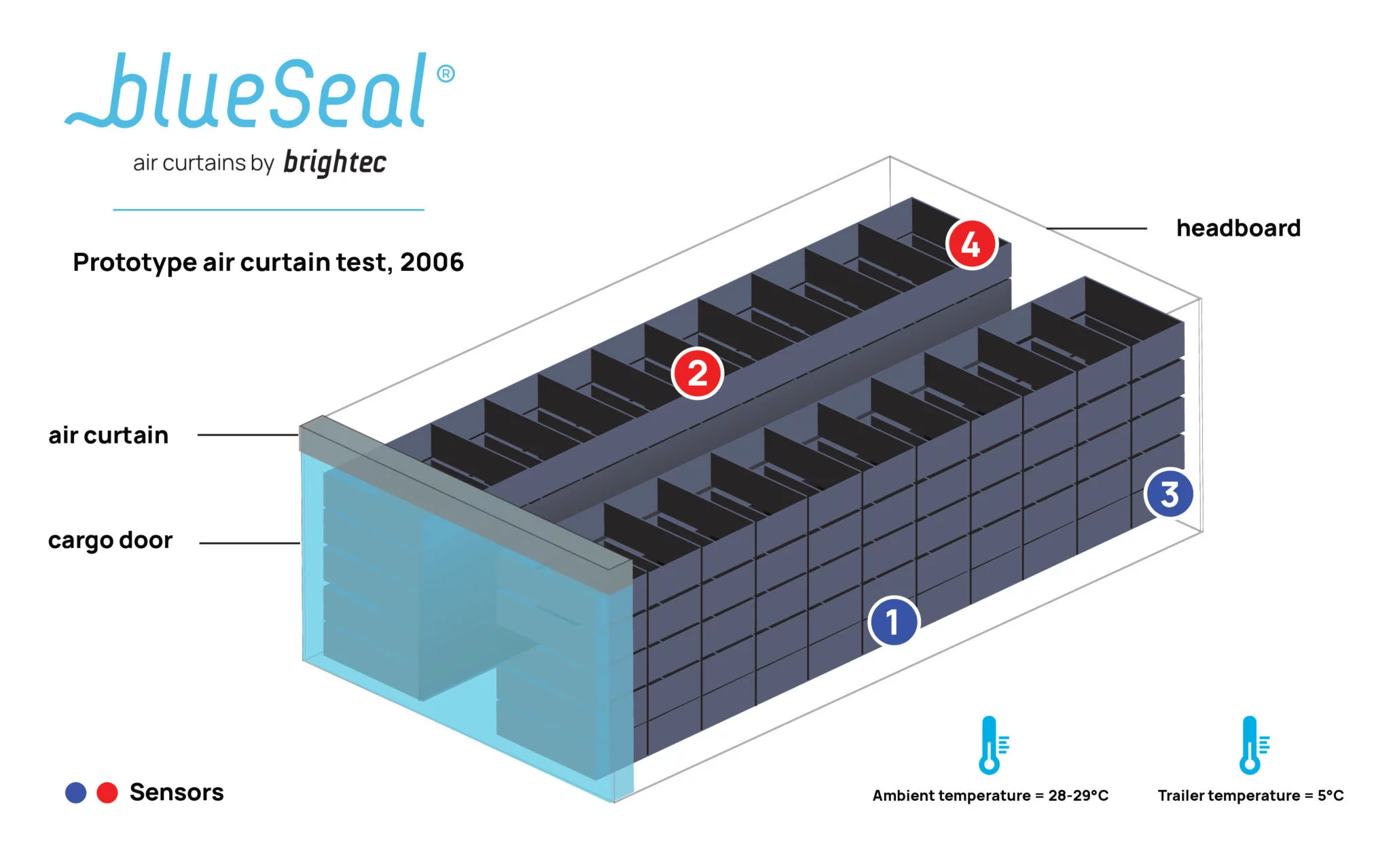

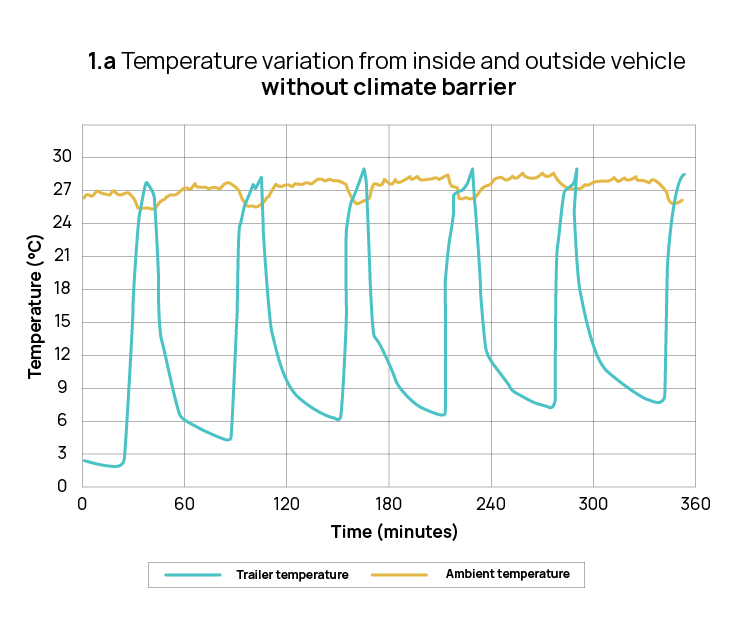

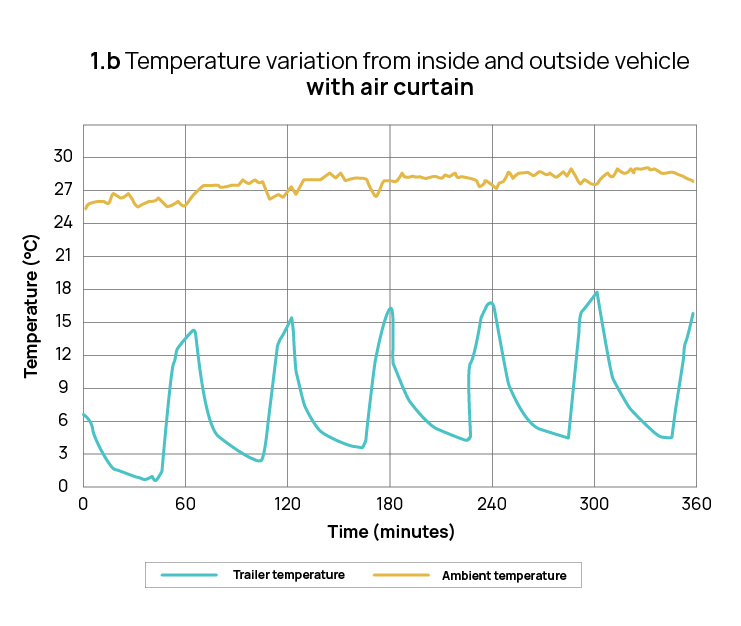

Figures 1a and 1b: Temperature of the inside air measured over 6 hours with 6 × 15 min door openings without any barrier (figure 1a) and with the air curtain (1b) above the rear doors. Ambient temperature: 28–29°C.

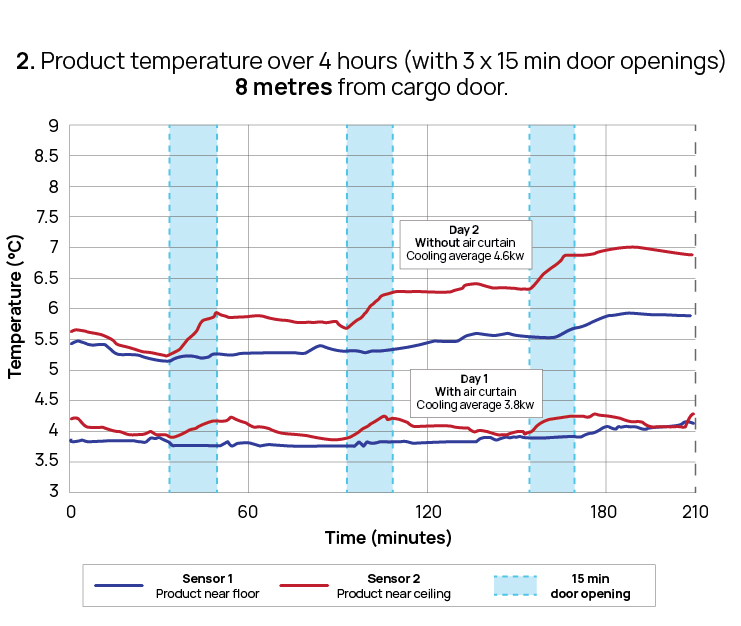

Figure 2: Temperature course inside two 1-litre cartons of water during 4 hrs with 3 × 15 min door openings without and with air curtain. Cooling machine operates at averages of 4.6 kW and 3.8 kW respectively. Cartons located on the same pallet approx. 8 m from the rear doors: sensor 2 (nearest ceiling), sensor 1 (nearest floor).

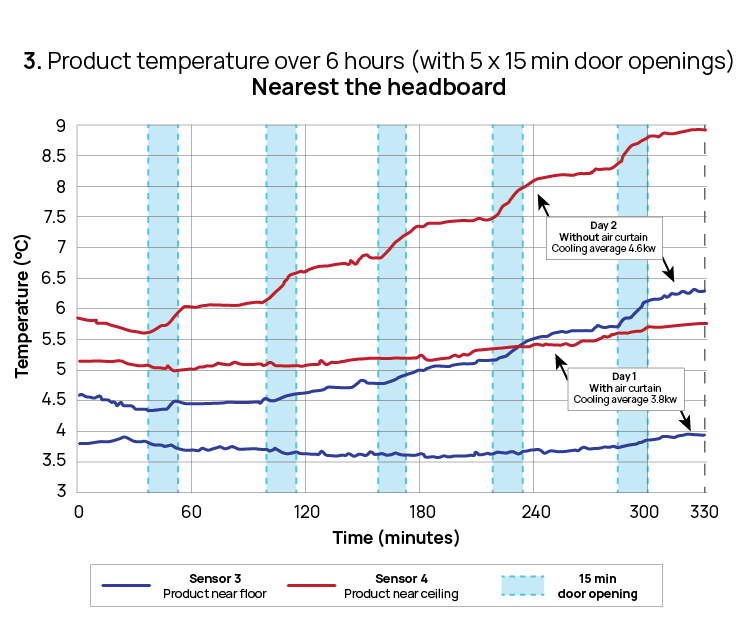

Figure 3: Temperature course inside two 1-litre cartons of water during 6 hrs with 5 × 15 min door openings without and with air curtain. Cooling machine operates at an average of 4.6 kW and 3.8 kW respectively. Two cartons located near headboard on the same pallet approx. 13 m from rear doors: sensor 4 (nearest ceiling), sensor 3 (nearest floor).

The Brief -From Eutectic Refrigeration to the History of Air Curtains for Energy-Efficient Refrigerated Transport

In 2005, Econcern proposed a new refrigerated truck concept using eutectic refrigeration as a more energy-efficient means of transporting cold produce. The main advantage was zero diesel consumption, offering the potential for a zero-emission cold chain.

However, the reduced cooling energy (kWh/kg) of eutectic systems made them vulnerable to energy loss during door openings. This challenge was particularly critical in food and pharmaceutical transport, where strict temperature control is essential to product integrity.

As The International Institute of Refrigeration notes:

“A significant number of health products… are heat-sensitive, and a change in storage temperature can render them unusable, inefficient, or dangerous.”

Traditionally, PVC strip curtains were used as physical climate barriers. However, operational inefficiencies-such as drivers moving them aside during unloading-often rendered them ineffective. Hygiene concerns and lack of maintenance further reduced their real-world benefits.

Discovering a Better Climate Barrier -The Birth of the Air Curtain

To address these issues, the Econcern team designed an air curtain specifically for refrigerated transport-a solution that removed physical obstruction for drivers while providing a continuous climate barrier.

Testing the First Air Curtain for Energy-Efficient Refrigerated Transport

Testing took place in a semi-trailer in a conditioned room at 28–29°C ambient temperature. Doors were opened for 15 minutes every hour over 6 hours. Cargo consisted of 22 pallets of 1-litre water cartons simulating milk transport.

Without air curtain:

- Internal air temperatures rose to 28°C during openings.

- Even after 45 minutes with doors closed, minimum temperatures kept rising (0°C to 8°C over 5 openings -see figure 1a).

- Cooling machine consumed 26.5 kWh without successfully restoring the desired 5°C.

With air curtain:

- Maximum internal air temperature limited to 18°C (figure 1b).

- Product temperatures nearly restored after each closing period (figures 2 & 3).

- Cooling energy use reduced to 21.8 kWh, with the air curtain operating at just 3.8 kW.

Conclusions -How the History of Air Curtains for Energy-Efficient Refrigerated Transport Shaped BlueSeal

The tests showed that air curtains can reduce energy use by 30–40% and significantly maintain cold chain integrity in multi-stop deliveries. This makes eutectic systems more viable and lowers operational costs for conventional diesel-powered TRUs.

Recognising the commercial potential, Hans Opdam founded Brightec to develop BlueSeal. Today, BlueSeal operates in over 22 countries with models tailored for trucks, trailers, and vans-continuing its role in the ongoing history of air curtains for energy-efficient refrigerated transport.

For more information on BlueSeal air curtains, please contact our Brightec consultants at [email protected]