The advantage of the BlueSeal air curtain in a vehicle with two and three rear doors

BlueSeal air curtains have been extensively tested in real-world and simulated conditions to evaluate their effectiveness in reducing energy use in transport refrigeration and protecting product quality.

This study focuses on their performance in a 7.5-metre truck under different rear door opening configurations – full, half, and one-third – to determine how each scenario impacts energy consumption and cold chain integrity.

Why Air Curtains for Reducing Energy Use in Trucks Are Essential

During distribution runs, drivers often open only the doors necessary for loading or unloading. This affects how much warm air enters and how well cold air is retained – directly impacting product temperature stability and energy use.

By understanding how door opening size influences cold chain performance, operators can apply air curtains for reducing energy use in trucks in the most effective configurations to keep products at optimal temperatures for more stops per run.

Testing Air Curtains for Reducing Energy Use in Trucks With Ice Cream

Ice cream was selected as the test product due to its extreme sensitivity to temperature fluctuations. Even slight warming and re-freezing can ruin its texture, making it an ideal benchmark for cold chain tests.

- Bulk packaged: stacked on pallets, depth 6m, height 1.2m, width 2.5m (Tbulk)

- Individual 0.5kg packages: exposed directly to cargo air (Tpackage) – a worst-case cold chain scenario.

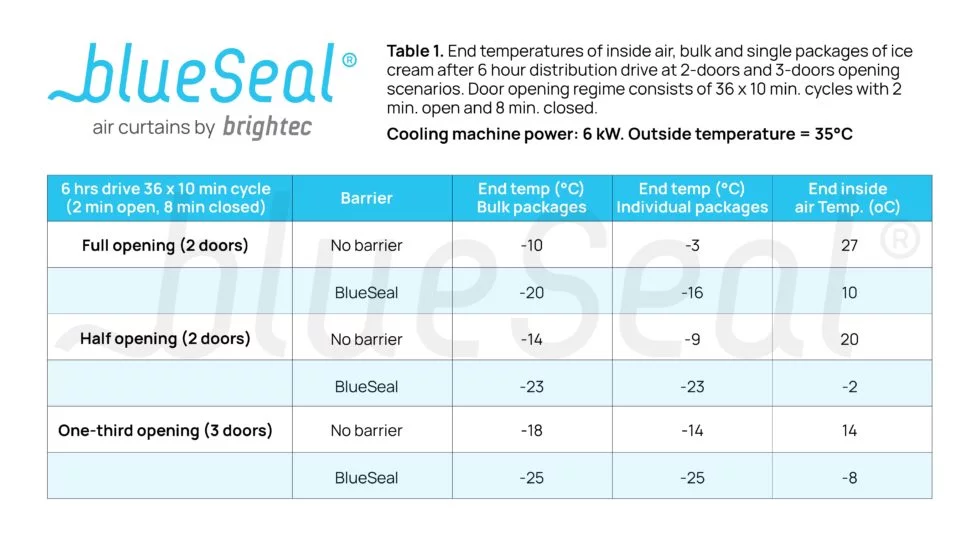

Simulations used a -25°C cargo set point, 35°C ambient temperature, and a 6kW cooling unit. The model replicated 36 delivery cycles over 6 hours (8 minutes closed, 2 minutes open) to reflect urban distribution conditions.

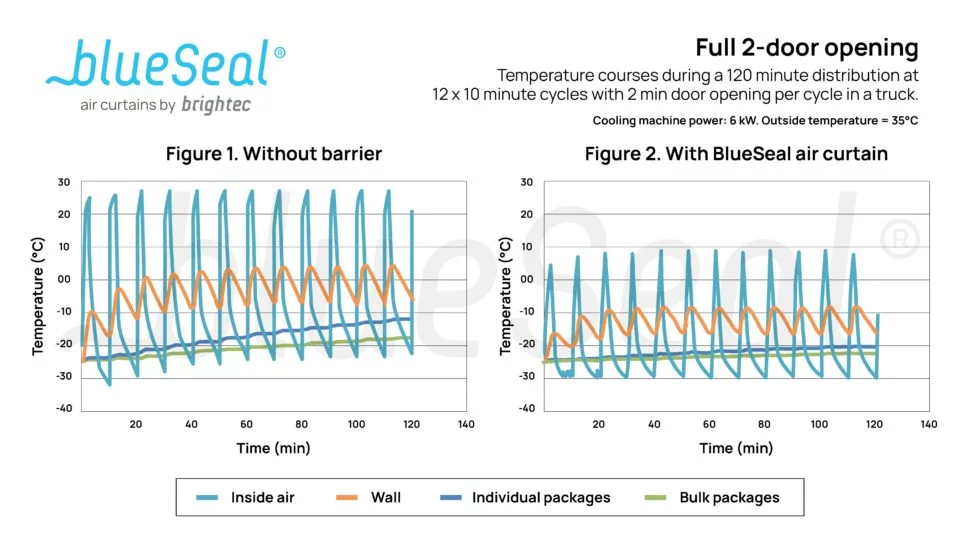

Full (Two-Door) Openings: Impact on Energy Use

Without air curtains:

- Inside air temperature rises by 24°C in just 2 minutes.

- Tpackage exceeds -18°C after 7 door openings.

- After 6 hours: Tbulk -10°C, Tpackage -3°C – unacceptable for ice cream transport.

With BlueSeal air curtains:

- Inside air temperature rises only 6°C after one opening.

- After 6 hours: Tbulk -20°C, Tpackage -16°C.

- Significant reduction in refrigeration load compared to no barrier.

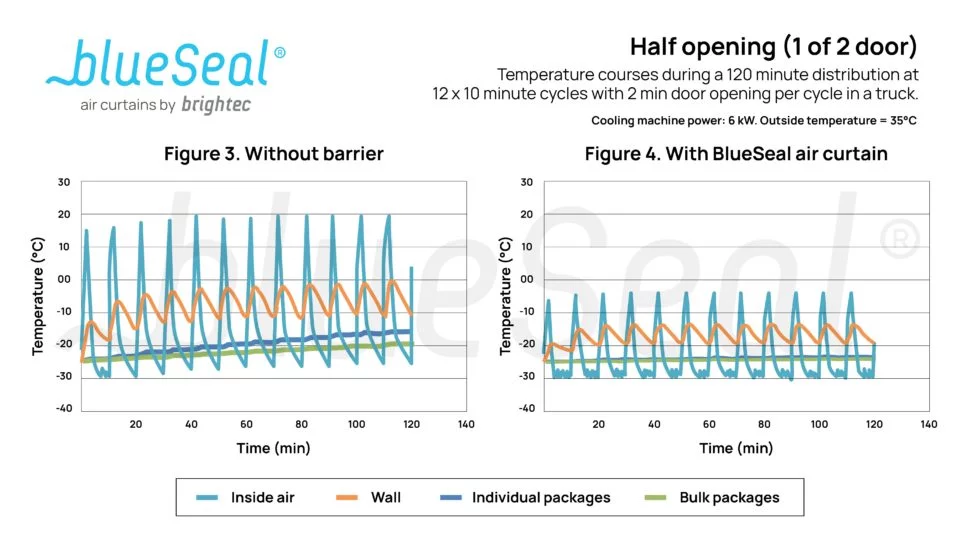

Half (One-Door) Openings: Better Energy Efficiency With Air Curtains

Without air curtains:

- Air temperature rises by 20°C.

- After 6 hours: Tbulk -14°C, Tpackage -9°C.

With BlueSeal air curtains:

- Air temperature rises only -2°C.

- After 6 hours: Tbulk and Tpackage both remain at -23°C.

- Cooling unit cycles less frequently, lowering energy use.

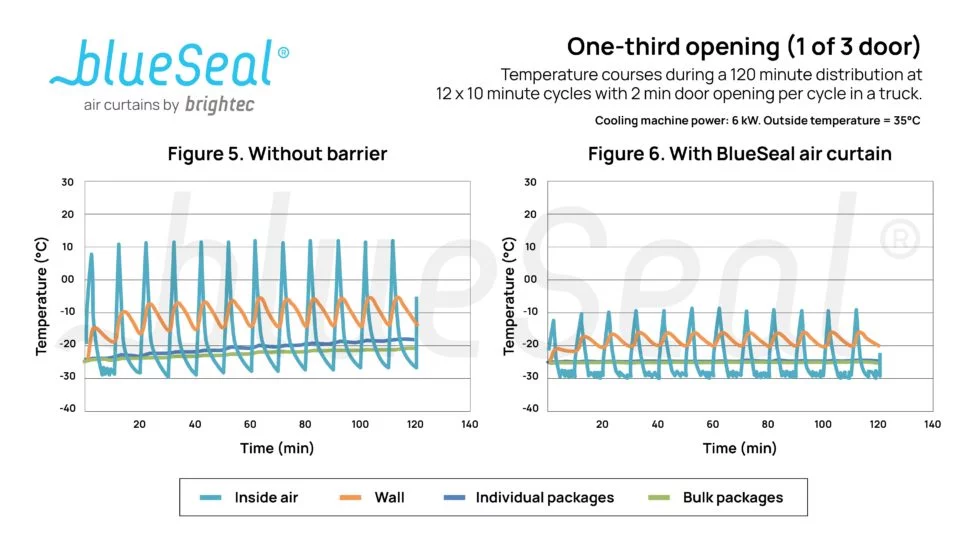

One-Third Door Openings: The Most Energy-Efficient Configuration

Without air curtains:

- End of 6 hours: Tbulk -18°C, Tpackage -14°C – above critical ATP limit.

With BlueSeal air curtains:

- After 6 hours: Tbulk and Tpackage both well below -18°C (Tpackage at -25°C).

- Lowest energy demand of all tested scenarios.

Key Conclusions on Air Curtains for Reducing Energy Use in Trucks

- Without air curtains, cold chain stability is compromised, especially with frequent or large door openings.

- With BlueSeal air curtains, product temperatures remain within ATP limits in most scenarios, and refrigeration energy demand is significantly reduced.

- One-third door openings with BlueSeal deliver the highest energy efficiency while preserving product quality.

By applying air curtains for reducing energy use in trucks, operators can achieve:

- Lower fuel and electricity costs for refrigeration units.

- Longer cold chain protection during deliveries.

- Better product quality on arrival.

For more information on BlueSeal air curtains, please contact our Brightec consultants at [email protected]