BlueSeal – Best Climate Control for Refrigerated Transport: How to Cut Diesel Costs and Protect Your Cold Chain

Temperature-controlled products such as food and pharmaceuticals rely on stable internal conditions during transport. Yet, during multi-stop delivery routes, each door opening can cause a rapid loss of cooled air, forcing refrigeration units to work harder and consume more fuel. The best climate control for refrigerated transport is therefore essential to reduce energy waste and maintain product integrity.

Why Climate Control for Refrigerated Transport Matters

Across cities and rural delivery networks, many carriers already use some form of climate barrier at vehicle doors to minimise cold loss. Traditionally, PVC strip curtains have been the standard choice, but more and more operators are adopting air curtains as the best climate control for refrigerated transport.

Without a climate barrier, cooling units face a significantly increased workload during distribution rides, especially on routes with multiple stops. This leads to higher diesel consumption, greater maintenance needs, and an increased environmental footprint.

Study Objective: Quantifying the Impact of No Climate Barrier

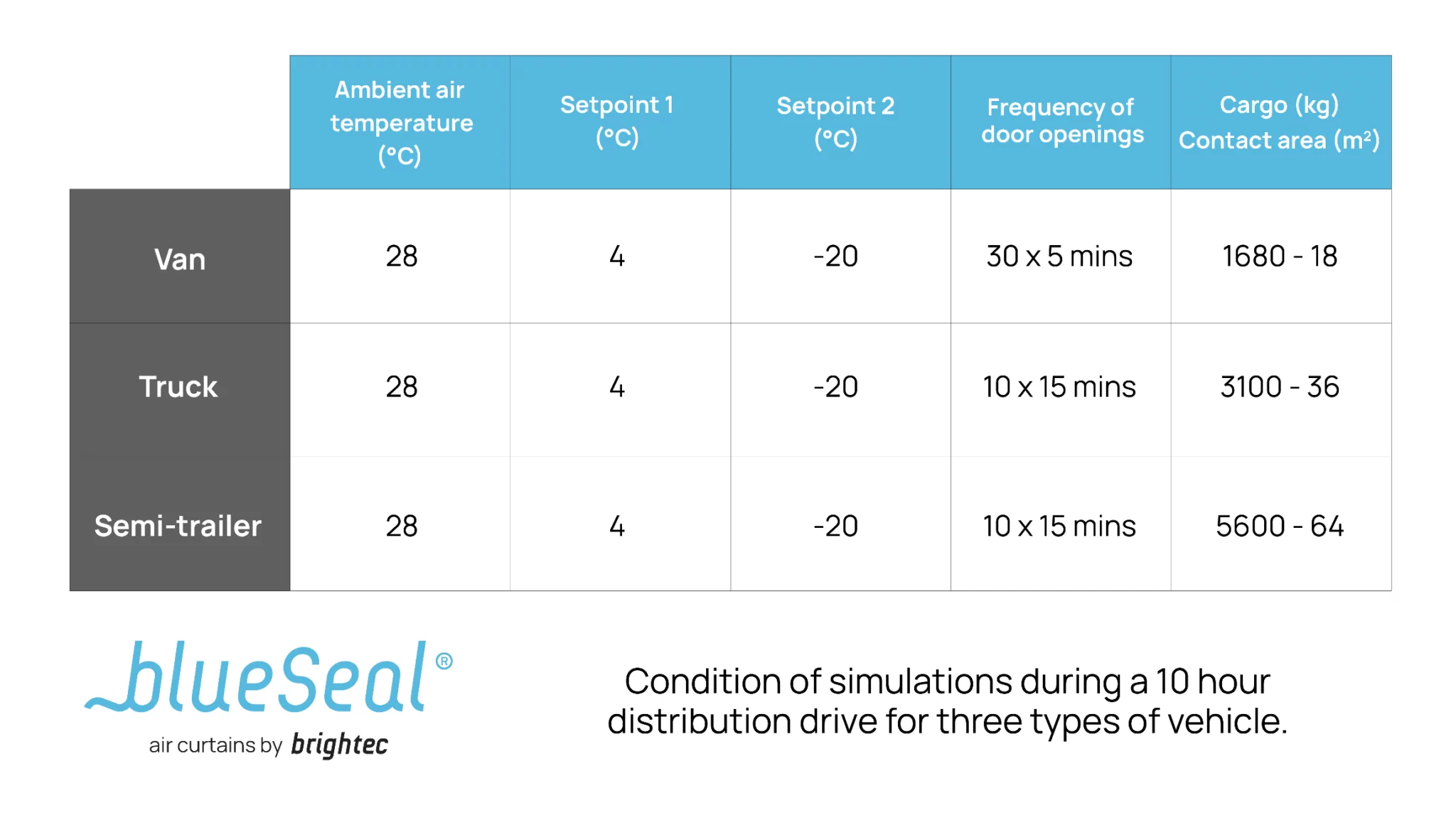

Using Brightec’s 2019 simulation model, we measured daily energy use for vehicles set at 4°C (chilled) and -20°C (frozen) in an ambient temperature of 28°C, across three vehicle types: vans, trucks, and semi-trailers.

BlueSeal was compared against no climate barrier to determine the effect on fuel use. Coefficients of performance were taken from real TRU test data: 4.0 kWh/L for chilled and 3.0 kWh/L for frozen scenarios.

Results Without a Climate Barrier

Even in transit with doors closed, active cooling is required to compensate for cold loss through the walls, floor, ceiling, and doors. This baseline demand is:

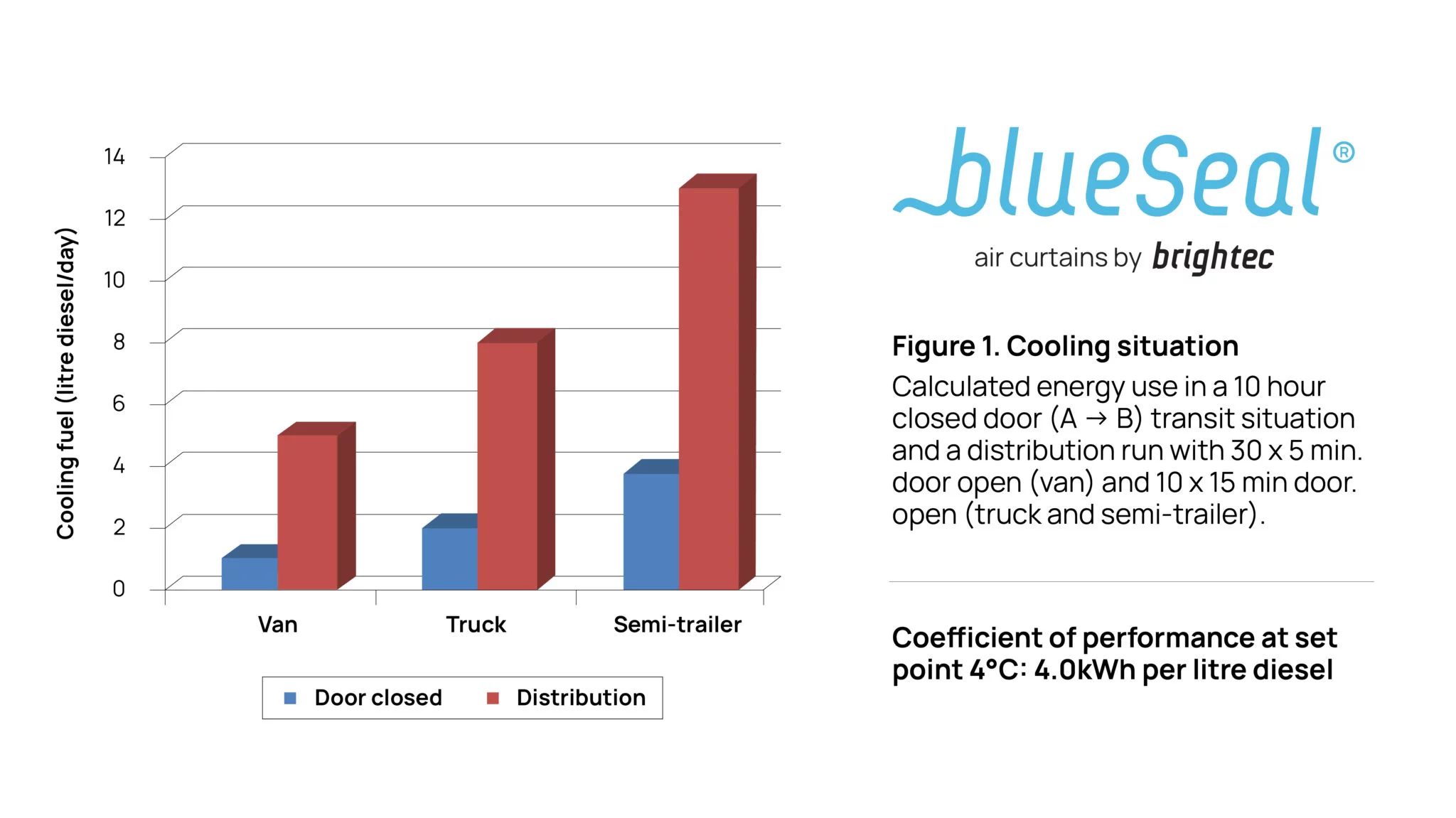

Chilled (4°C): 4, 8, and 14 kWh/day (1, 2, and 3.5 litres diesel) for van, truck, and trailer respectively.

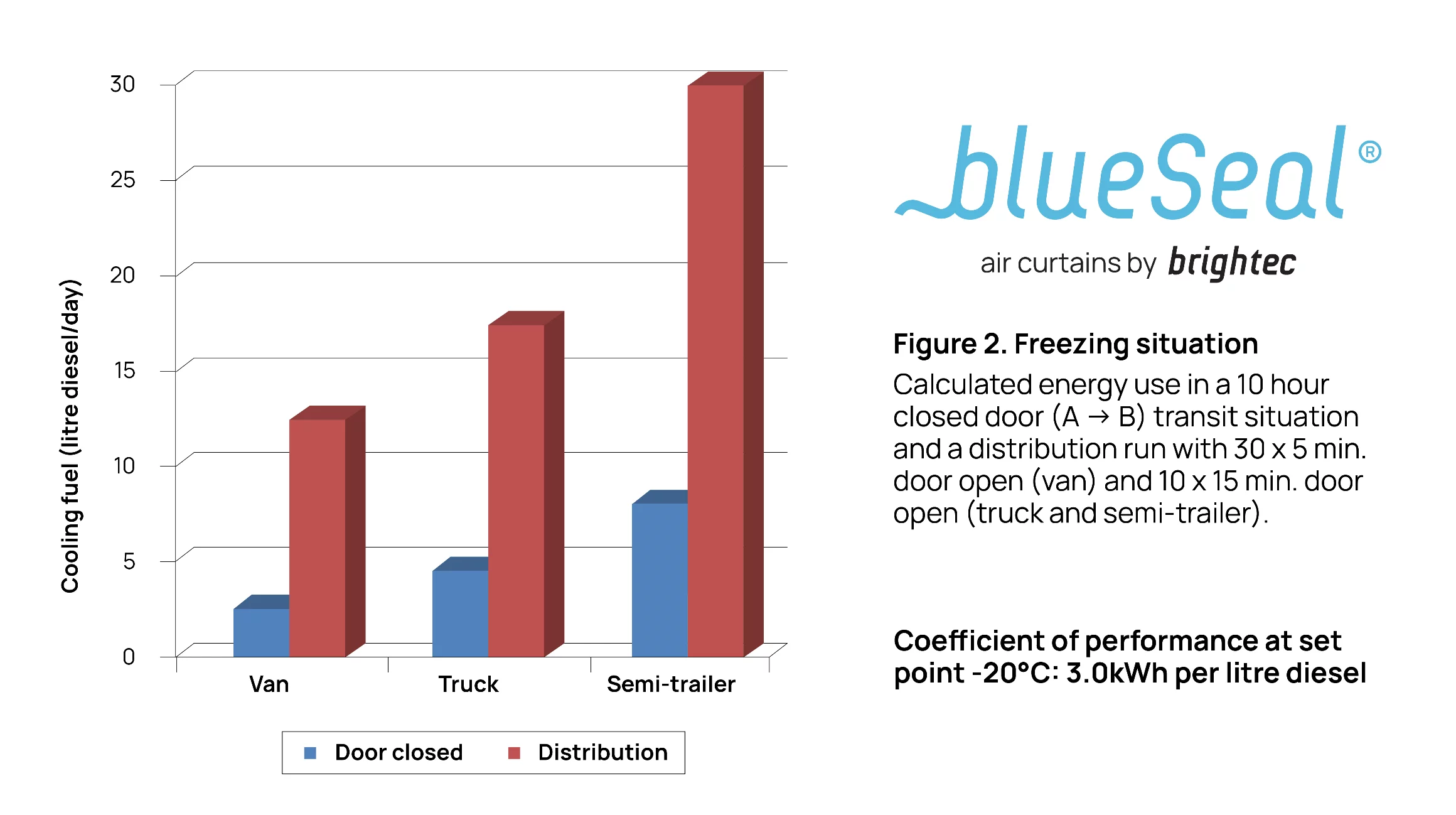

Frozen (-20°C): 2.5, 4.5, and 8 litres diesel/day for van, truck, and trailer respectively.

When no climate barrier is used during distribution routes:

Chilled (4°C): 20, 32, and 50 kWh/day (5, 8, and 12.5 litres diesel).

Frozen (-20°C): 12.5, 17.5, and 30 litres diesel/day.

Door openings increase cooling demand by 3 to 5.5 times, adding 200-450% more energy use. In semi-trailers, this means up to an additional 9 litres diesel/day for chilled and 22.5 litres/day for frozen goods.

Annual cost of avoiding a climate barrier

Based on 250 operational days/year at an average ambient temperature of 16°C:

Chilled: Extra 500 L (vans), 750 L (trucks), 1,125 L (semi-trailers) diesel/year.

Frozen: Extra 1,850 L (vans), 2,380 L (trucks), 4,600 L (semi-trailers) diesel/year.

This doesn’t include the additional maintenance costs from refrigeration units working harder.

Why Air Curtains Offer the Best Climate Control for Refrigerated Transport

BlueSeal air curtains create an invisible barrier that reduces temperature loss during door openings without obstructing driver movement. Unlike PVC strips, they improve hygiene and eliminate the need for physical contact.

Key benefits:

- Lower diesel use by up to thousands of litres/year.

- Maintain consistent product temperatures across delivery routes.

- Reduce wear and tear on refrigeration equipment.

Conclusion: The Best Climate Control for Refrigerated Transport Saves Money

Door openings can increase fuel use by thousands of litres annually. Implementing the best climate control for refrigerated transport, such as BlueSeal air curtains, significantly cuts diesel costs, reduces environmental impact, and protects your cold chain.

Future studies will explore the full cost-saving potential of this solution across different climates and delivery patterns.

For more information on BlueSeal air curtains, please contact our Brightec consultants at [email protected]